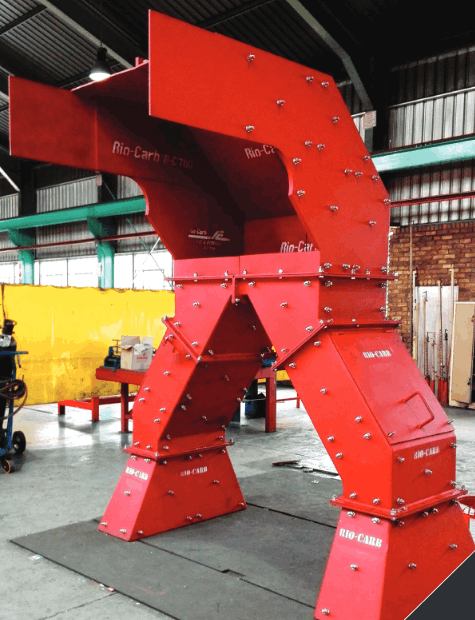

Chromium Carbide CrC Overlay

• Ideal for sliding abrasion (chutes, cyclones, pipes etc).• Cost effective. Cuts downtime costs.

• Unique MaxCSTM system for Maximum Carbide Saturation.

• Outlast normal ‘400’ and ‘500’ materials by 8-12 times.

• Withstands heat up to 600°C.

• Can be countersunk and holed, stud-welded, rolled and fabricated.

• Thickness from 6mm (3/3) to 30mm (20mm CrC on the 10mm base).